Preparing Icelandic Wool

My journey of preparing wool from fleece for spinning begins here with a piece of

Icelandic sheep fleece that Hans brought me from his trip to North Carolina. He was away 3 weeks for a business trip and I stationed at home to look after the house. At first I want him to just bring back some roving, but he thought that it'll be nice for me to try some new things. So here I got a big piece of fleece -- and they DO smell like sheep. Sommer the German Sephred and Jati the big cat were both so excited to smell and see the fleece.

A friend I met in spinning class volunterred to show me how to do the washing process. We met up at the house and had our little experiment on washing the fleece. It was less intimidated than I though -- although the process is LONG. At first I thought that I would just send the rest of the fleec to a mill so that thye can process for me. But to think about how much it will cost ($200 to process a piece of $20 fleece), I don't think it's worth it. So somehow, I decided to wash the wholething myself. In retrospect, there are many things that I would have done differently. However, it's a good experience and I'm glad to learn some new stuff in the process.

What I've learnt:

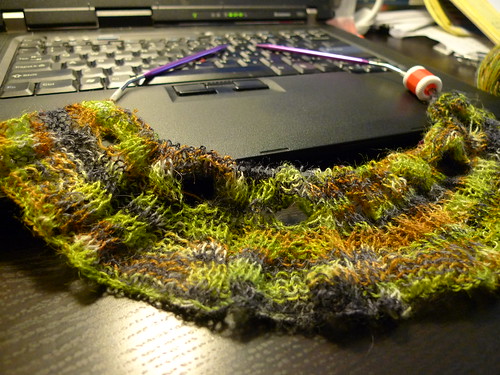

- process of preparing fiber including washing the fleece to get rid of the dirt and lanolin (i.e. the 'oil' in the undercoat); combing the fiber to get the fine vegetable matters and 'dandruff' of the sheep away -- and this fleece I got had a lot of dandruff in it

- felting the fleece in the process of washing made the combing process really messy and annoying.. I tried to hard to separate the undercoat...

- washing with small container seems less efficient but more effective to get the dirt out

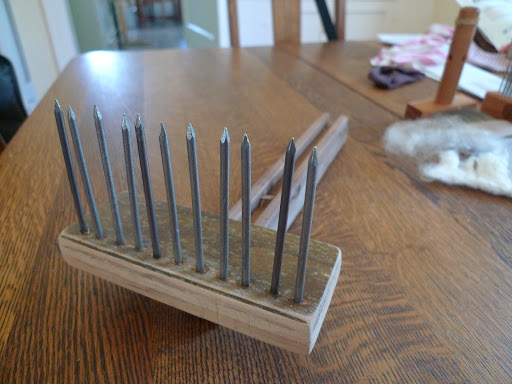

- how to use a wool comb, and evenutally, made one for myself (see here) !!

Washing them

Drying

What I would have done better next time:

- know the nature of the fleece that I'm dealing with better

- save the water to water the plants in the garden from the very begining

- separte the wool more before I put them into the water, which would made it easier to separate in the combing process!!

Useful resources to read more about preparing Iceland Sheep Fleece: